SMT Splice Products

With SMD Splice Solutions, increase efficiency easily

Minimize Machine Downtime

Reduce Component Loss

Increase Your Production Efficiency

Meet High Standards

Visit our new website and see for yourself.

Discover how our fast delivery times, exclusive designs, and innovations can give you a decisive competitive advantage.

👉 Get informed now: www.SMTSpliceTapes.de

SMT Splice Products

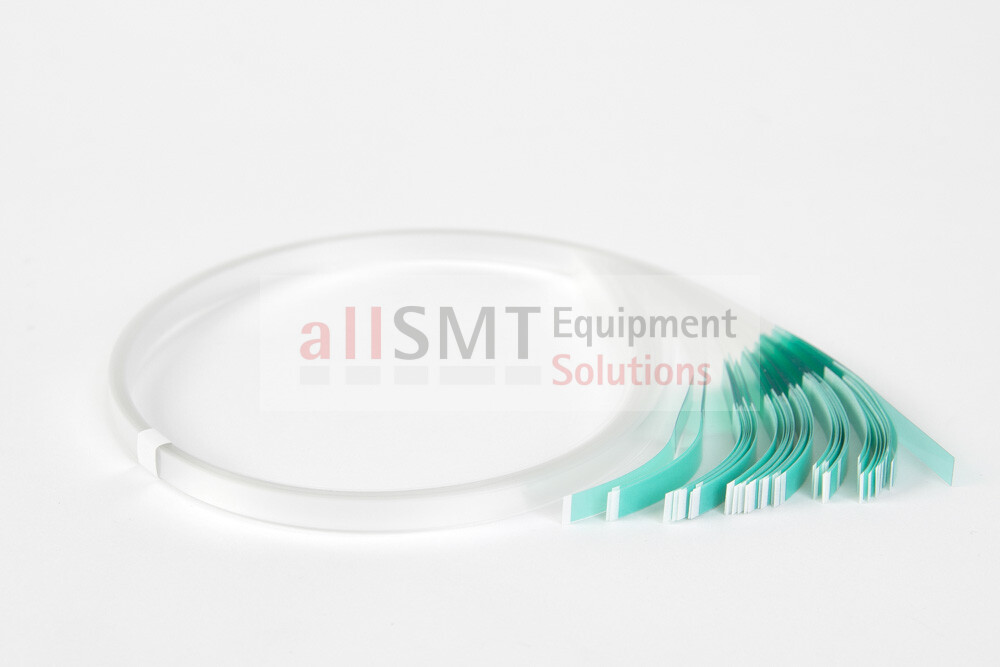

SMD Splice Tapes, SMT Cover Tape Extenders and Tools for your Electronicmanufacturing

Experience and innovations all around the Topic " the right way to splice"

The company allSMT GmbH & Co. KG, based in the Aachen city region, has been distributing SMD splice products and consumables licensed from Siemens (ASM), among others, for more than 10 years. Long-standing customers from all over the Wolrd purchase the top splice products from allSMT, including tape and reel or contract taping providers who offer re-reeling as an SMT service. This underlines the excellent quality of the splice tapes, smt splice clip solutions and splice tools. Our legally protected in-house developments for process improvement as well as handling optimisation round off the portfolio of allSMT, founded in 2003. Test our solutions such as SMT Cover Tape Externders, Reel-Sealers and SMT Tools without obligation. We look forward to your enquiries.

WHAT IS SPLICING ANYWAY ?

Tape splicing allows you to "refill" taped components by splicing a new tape without machine downtime.When splicing taped components, you connect the end of the paper or blister tape, which is inserted in the feed module, with the beginning of the new tape.

The different colours of our splice products:

Splice Tapes and SMD Tape Extensions are available in different colours. The most commonly used are: yellow, blue, green, black, pink-pink and the splice tapes that contain metal.

From 2005/2006 the blue splice was introduced in Europe by the company allSMT. These tapes have a special adhesive strength and can therefore be used flexibly in the belt conveyors (feeders) of various manufacturers such as Siplace, Fuji, Juki, Yamaha, Assembleon, Samsung etc. In the meantime, however, this has changed and the adhesive strength is equally "strong" in all our splice products, so that problems in belt conveyors (feeders) occur very rarely and are usually due to incorrect use.

A further requirement for splice tapes has come from the splice detection technology. For manufacturers like Panasonic or Fuji special colour have been introduced. These splice tapes were then produced in black or in a metal optic, so that the cameras or sensors can detect the tapes in and on the feeder.

The different shapes of our splice products:

Over the years, different shapes have been developed. The Clip & Splice series is particularly noteworthy. This series combines the Single Splice Tape with the Splice Clip on a carrier film. The result here; less shrinkage, even easier handling than before and a stable connection even of plastic straps.

The shapes of the splice products also vary from manufacturer to manufacturer. Special tapes are available for Panasonic NPM, CM series, Fuji NXT, Samsung, Juki SMT pick and place machines, among others.

The standard SMD Splice Tapes are manufactured with a thickness of 25µm PET film with a total thickness of 53µm. Thinner films are also available on request.

Please contact us for further details.

Call us and let us advise you in a personal conversation. CONTACT US